I. The technical requirements of CNC machine tools for frequency converters

1. Requires large low-frequency torque;

2. The dynamic response speed of the torque is fast, and the speed stabilization accuracy is high;

3. Decelerate and stop immediately;

4. Carry out the motor parameter self-learning;

5. Various requirements of frequency command and running command.

Taking the application of Yuanxin YX8000 series high-performance vector inverter in a CNC machine tool factory as an example, the following describes the frequency conversion speed control technology of CNC machine tools.

The inverter has the following superior performance:

1. Adopting advanced flux control algorithm, realizing the real speed sensorless vector control, the control performance is much better than the traditional V/F control method;

2. Large starting torque, 0.21Hz / 150% ;

3. Carrier frequency range 0-14KHz; adaptively adjusted according to the temperature and the load;

4. Providing excellent 0-10V/0(4) -20mA analog interfaces, the interface can be compatible with most of the CNC system, which is versatile;

5. Strong overload capacity, 150% rated output current for one minute;

6. Providing multi-functional output terminal signals, such as fault output signal, running signal, speed-reached signal, which can well satisfy the need for monitoring the system on the spindle speed status.

II. Parameter setting

|

Function code |

Name |

Set value |

Remarks |

|

P0.01 |

The frequency setting channel is: VI analog setting |

5 |

VI analog given |

|

P0.03 |

Terminal run command channel is valid |

1 |

Terminal operation |

|

P0.06 |

Maximum frequency of inverter operation |

100 |

|

|

P0.17 |

Acceleration time 1 |

1 |

Set according to site conditions

|

|

P0.18 |

Deceleration time 1 |

1 |

|

|

P0.19 |

Maximum output frequency |

100 |

|

|

P1.05 |

Frequency corresponding to VI maximum setting |

100 |

|

|

P2.05 |

Stop mode: deceleration + DC braking |

2 |

|

Inverter wiring terminal sequence |

|

|

FWD—COM |

Forward signal |

|

REV—COM |

Reverse signal |

|

GND—10V |

VI analog setting |

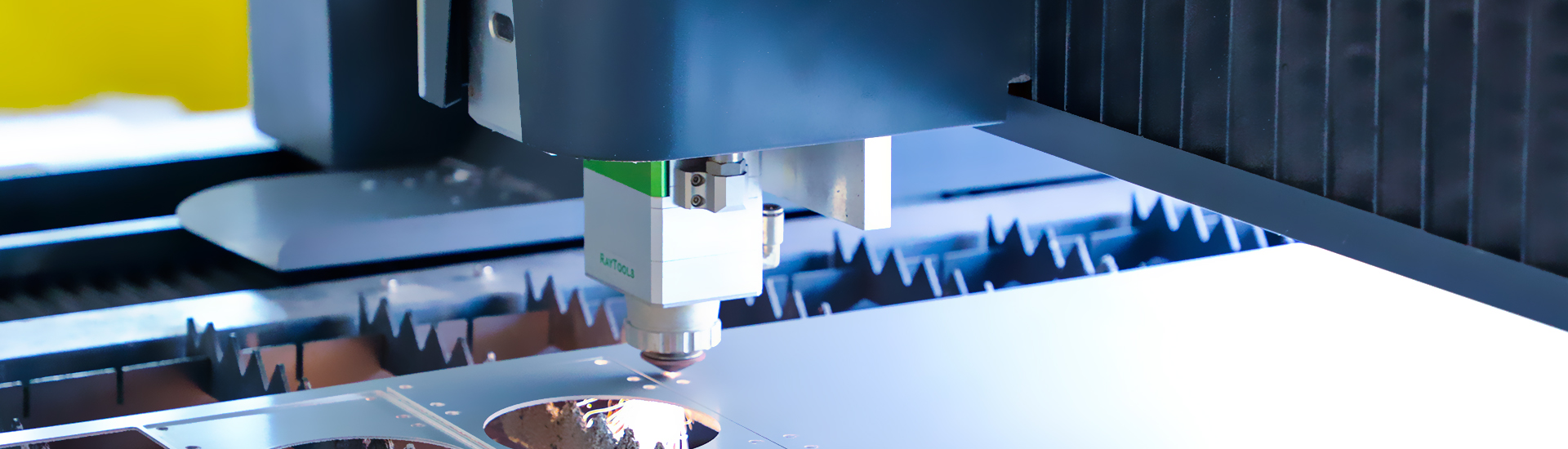

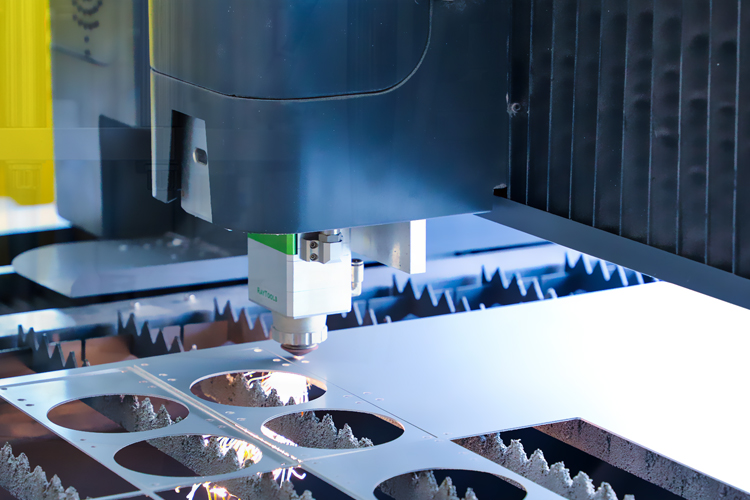

IV. Onsite pictures of application on CNC machine