I. Overview

As the electronic speed control equipment with very high degree of automation, the frequency converter has wide speed range, stable speed and high precision with automatic control, and is easy to operate. It has become an incomparable product for other speed control equipment. It is widely used in all walks of life. However, before adopting frequency inverters, electromagnetic motors or DC motors are generally used in pipe pile machines for speed control. Due to the low speed regulation precision of the electromagnetic motor, limited range of speed regulation, sometimes it can’t meet the requirement for high speed. Moreover, because the pipe piles need to run at different speeds and time periods during the production process, the operator has to adjust the speed manually, and calculate the running time of different speeds with a stopwatch. In this way, the labor intensity of the operator is extremely high, and the production efficiency is also very low. If the operators are absent-minded, the pipe piles may be scrapped, which causes huge losses to the factory.

In the entire production process of pipe piles, forming on the centrifuge is the most critical link. This process is divided into three stages: distributing, secondary transmission, and compacting. Each stage has different requirements for the rotation speed and time of the pipe pile. And for different wall thickness and length of the tubular pile, the speed and time requirements of these three phases are not the same, which requires that the inverter could adjust the motor according to different pipe piles at different working stages, time periods, speeds and durations to ensure the quality of pipe piles. Yuanxin has developed YX3400 series special frequency inverter which is suitable for various pipe pile machines according to the features of pipe pile technology. It has a large starting torque. According to the different sizes of the pipe piles, raw materials and other process requirements, five operating modes of pipe piles can be set respectively, and each mode can be freely set with four different operating frequency and operation time, greatly improving production efficiency, achieving good results, and reducing the labor intensity.

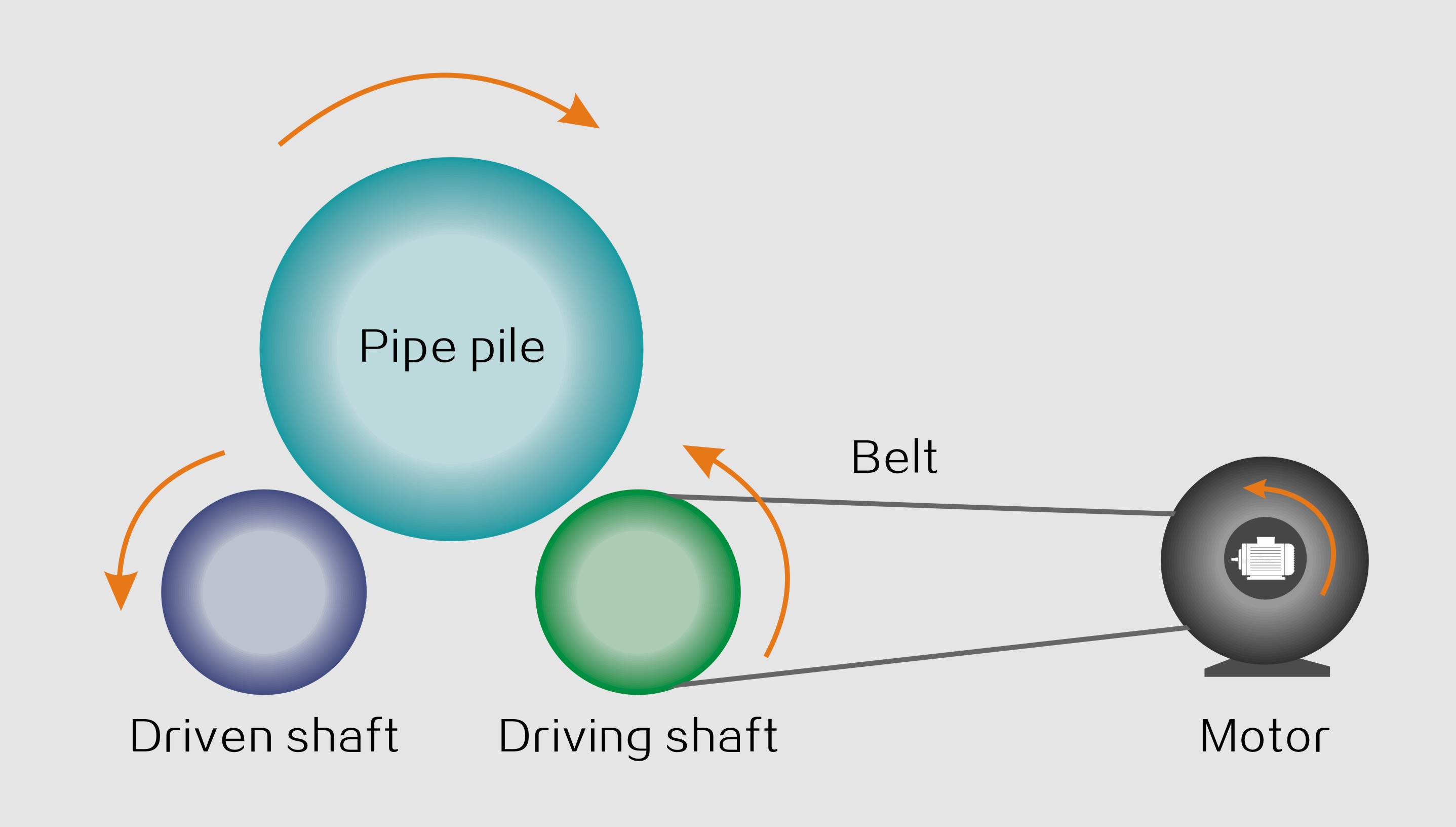

II. Working principle

The pipe pile is placed at the angle between the driving shaft and the driven shaft. The motor drives the driving shaft to rotate, and the pipe pile is driven by the friction of the driving shaft to rotate at a certain speed and time.

III. Some technical characteristics of Yuanxin YX3400 pipe pile machine inverter

1. Five working modes can be preset in advance, and each mode can be set with four different speeds and different running times. The operating mode can be selected according to the size of the pile and the type of raw material;

2. The start and stop of the system are controlled by a two-wire system, which can be realized with buttons;

3. Three sections of V/F curve can be set manually to make the pipe pile machine start smoothly and powerfully at low frequency, ensuring the continuity of the system operation;

4. Breakpoint memory function: if the system has to stop running for some reason, and after restarting, the inverter can continue to work at the same frequency of last time without manual regulation.

IV. Basic parameter setting of YX3400 pipe pile machine inverter

|

Parameter setting of YX3400 pipe pile machine inverter |

|||

|

Function code |

Name |

Setting value |

Remarks |

|

P0.03 |

Run command channel |

1 |

Terminal operation |

|

P0.04 |

Rotation direction |

1 0 |

Reversal is not allowed |

|

P0.09 |

Torque boost |

3.0 |

Set the torque reasonably |

|

P0.17 |

Acceleration time 1 |

15 |

Set according to site conditions |

|

P0.18 |

Deceleration time 1 |

50 |

|

|

P0.22 |

V/F curve setting |

4 |

Multistage V/F curve |

|

P0.23 |

V/F frequency value F3 |

41 |

Set according to site conditions |

|

P0.24 |

V/F voltage value v3 |

100 |

|

|

P0.25 |

V/F frequency value F2 |

18 |

|

|

P0.26 |

V/F voltage value v2 |

36 |

|

|

P0.27 |

V/F frequency value F1 |

5 |

|

|

P0.28 |

V/F voltage value v1 |

12 |

|

|

P2.05 |

Stop mode |

1 |

Free stop |

|

P4.08 |

Start-stop operation mode selection |

0 |

FWD: start, REV: stop |

|

P7.00 |

Selection of PLC operation mode of pipe pile |

0 |

Record the stage and frequency when power cut off |

|

Continue to run at the frequency at the moment of interruption |

|||

|

Stop after single cycle |

|||

|

P7.01 |

Mode setting for pipe pile machine |

1 |

Mode 1 |

|

P7.02 |

First operating frequency for mode 1 |

18 |

Set according to the actual situation on site |

|

P7.03 |

First running time for mode 1 |

90 |

|

|

P7.04 |

Second operating frequency for mode 1 |

28 |

|

|

P7.05 |

Second running time for mode 1 |

60 |

|

|

P7.06 |

Third operating frequency for mode 1 |

35 |

|

|

P7.07 |

Third running time for mode 1 |

60 |

|

|

P7.08 |

Fourth operating frequency for mode 1 |

41 |

|

|

P7.09 |

Fourth running time for mode 1 |

420 |

|

Note: The above parameters only set those parameters of mode 1 for P7.02-P7.09. Customers can set the other four modes through parameters P7.10-P7.41 according to actual needs.

V. Matters needing attention

1. Keep the working environment dry and ventilated and prevent the mud thrown from the pipe piles from splashing into the inverter cabinet;

2. Set the torque reasonably according to the actual situation to achieve the best effect;

3. The system should be grounded reliably to prevent the danger of electric shock to the operator.

VII. Onsite pictures