I. Overview

With the increasingly rapid development of the plastics industry in recent years, the injection molding industry is also facing an opportunity to leap.. But at the same time, competition in the industry is becoming increasingly fierce. In addition to focusing on product quality and brands, manufacturers are also paying more and more attention to the control of production costs. According to the process of injection molding machine, the cost of electrical energy consumption accounts for a large proportion to the cost of injection molding products. Therefore, whether the power loss can be effectively reduced has attracted the attention of various injection molding machine manufacturers and users. To meet the market demand, Yuanxin Electric designed and launched the asynchronous servo drive. The Yuanxin asynchronous servo drive adopts the closed-loop control, detects the pressure and flow signal of the injection molding machine through sensors, and automatically adjusts the speed of the oil pump motor to make the fuel supply consistent with the demand of the injection molding machine, so that the energy consumption of the motor throughout the changing load range has been minimized as required, and the stable and accurate operation of the motor is ensured, which not only guarantees product quality but also saves electrical energy, and truly be economical and practical.

II. Technological Process

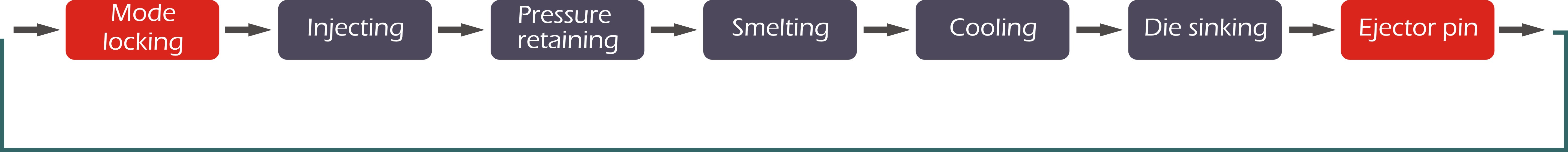

Schematic diagram of production Process

![]()

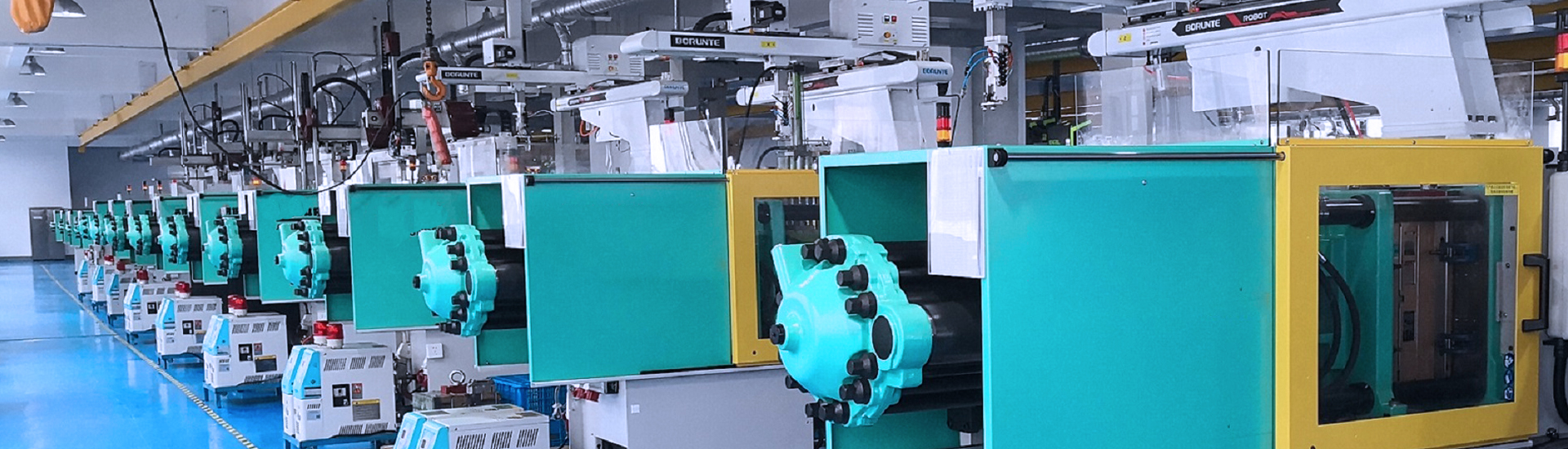

Schematic diagram of injection molding machine

When the injection molding machine of a pressure system is running, each action is driven by a proportional valve, but the load of each process is different. Except for high-pressure mold locking, injecting and smelting, the other processes are lightly loaded. Especially cooling, the energy is totally waste. We can change the speed of the motor during each process to make the oil supply of the oil pump consistent with the flow demand of the injection molding machine. To eliminate the overflow phenomenon, the motor can be completely stopped when cooling in order to achieve energy saving.

III. Parameter setting of Yuanxin asynchronous servo

|

Main parameter setting of Yuanxin asynchronous servo |

|||

|

Function code |

Name |

Set value |

Remarks |

|

P0.00 |

Frequency setting channel |

10 |

|

|

P0.02 |

Run command channel |

1 |

Terminal operation |

|

P0.10 |

Acceleration time 1 |

0.2 |

Setting according to actual situation |

|

P0.11 |

Deceleration time 1 |

0.2 |

|

|

P1.00 |

VI minimum setting |

50 |

Setting according to actual situation |

|

P1.02 |

VI maximum setting |

5 |

|

|

P1.05 |

CI minimum setting |

0.1 |

|

|

P1.07 |

CI maximum setting |

9 |

|

|

P8.01 |

Motor rated power |

22 |

|

|

P8.02 |

Motor rated speed |

1460 |

|

|

P8.03 |

Motor rated current |

44 |

|

|

P8.00 |

Motor parameter self-learning |

1 |

Comprehensive self-learning of parameters |

IV. Main advantages of the asynchronous servo after the transformation

1. The power saving effect is obvious, and the power-saving rate generally reaches 25% ~ 70%;

2. Excellent soft-start performance, two analog inputs, fast dynamic response, and fully meeting the process requirements of the injection molding machine;

3. Super overload capacity, built-in power frequency spare circuit, to further ensure the normal production;

4. Extend the service life of the motor, reduce noise pollution, and improve work efficiency.

V. Analysis on power-saving rate

The power-saving rate mainly depends on the mold process parameters, the speed value of mold process parameters (0-99%) is most related with power-saving. The smaller the speed value , the higher power-saving rate. If the speed value of mold is generally between (0-30%), the power-saving rate can reach to 70%; if the injection and melting speed value of mold generally above 90% and without net cooling time ( the mold is sunk when the glue is just melted ), then the power-saving rate can only reach about 25%.

Take a Haitian HTF470 dosing pump injection molding machine with 22 KW motor power for example, with using the Yuanxin asynchronous servo power saver:

Assuming the motor loaded rate (loaded rate=motor power consumption per hour ÷motor power) is 40%, the power consumption per hour is:

22KW×40=8.8 DEGREES

To work 24 hours a day, 26 days a month, with the average daily electricity fee of 0.8 RMB, the monthly electricity fee is:

8.8 DEGREES ×24 HOURS ×26 DAYS×0.8 RMB /DEGREE =4393 RMB

Assuming a power saving rate of 45%, the monthly electricity bill saving benefit is:

4392 RMB× 45% = 1976.4 RMB